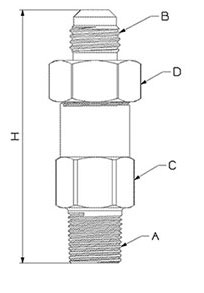

| Part No. | NPT A (in) |

Flare B(in) |

C Hex a/f (mm) |

D Hex a/f (mm) |

H (mm) |

App Wt (gm) |

|---|---|---|---|---|---|---|

| PRV-06 | 1/4 | 22 | 54.7 | 90 | ||

| PRV-10 | 3/8 | 3/8 | 25.4 | 22 | 80 | 158 |

| PRV-12 | 1/2 | 1/2 | 35 | 32 | 100 | 393 |

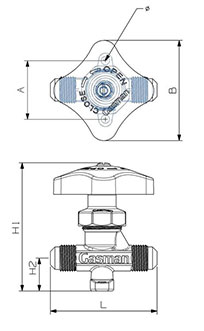

| PART NO | A | B | C | H1 | H2 | H3 | L1 | L2 |

|---|---|---|---|---|---|---|---|---|

| AV-22 | 7/8 ODS | 7/8 ODS | 7/16UNF | 154 | 61.8 | 42 | 67.5 | 34 |

| AV-28 | 1-1/8 ODS | 1-1/8 ODS | 7/16UNF | 154 | 61.8 | 42 | 72 | 135 |

| AV-35 | 1-3/8 ODS | 1-3/8 ODS | 7/16UNF | 184.5 | 76 | 46 | 79.1 | 38.1 |

| AV-42 | 1-5/8 ODS | 1-5/8 ODS | 7/16UNF | 184.5 | 76 | 46 | 79.1 | 38.1 |

| AV-55 | 2.1/8 ODS | 2.1/8 ODS | 7/16UNF | 213.5 | 93 | 60 | 101 | 44 |

| AV-67 | 2.5/8 ODS | 2.5/8 ODS | 7/16UNF | 238.5 | 100.7 | 62 | 115 | 55.5 |

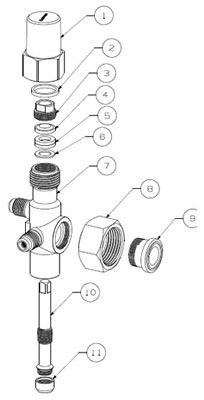

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | Qty. |

| 1 | Cap | Plated MS | 1 |

| 2 | Washer | Neoprene | 1 |

| 3 | Gland Nut | Brass | 1 |

| 4 | Gland Packing | Neoprene | 1 |

| 5 | Washer | Brass | 2 |

| 6 | Gland Packing | Grafseal | 2/3/5 |

| 7 | Body | Brass Forging BS 218 |

1 |

| 8 | Seat | SS 304 | 1 |

| 9 | Spindle | SS 304 | 1 |

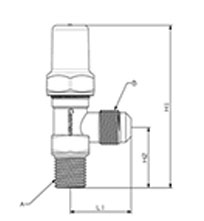

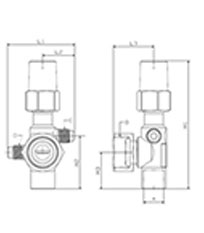

| Part No. | NPT A (in) |

Flare B(in) |

L1 (mm) |

H1 (mm) |

H2 (mm) |

WT (gm) |

|---|---|---|---|---|---|---|

| AV-06 | 1/4 | 1/4 | 27 | 66 | 27.5 | 85 |

| AV-10 | 3/8 | 3/8 | 31 | 73.5 | 40.5 | 125 |

| AV-10B | 3/8 | 1/4 | 31 | 73.5 | 40.5 | 122 |

| Part No. | NPT A (in) |

Flare B(in) |

L1 (mm) |

H1 (mm) |

H2 (mm) |

WT (gm) |

|---|---|---|---|---|---|---|

| AV-06F | 1/4 | 1/4 | 27 | 66 | 27.5 | 83 |

| AV-10F | 3/8 | 3/8 | 31 | 73.5 | 40.5 | 122 |

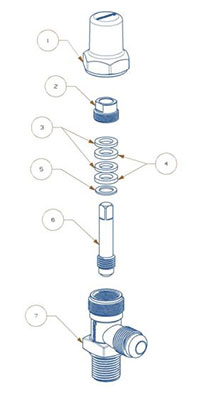

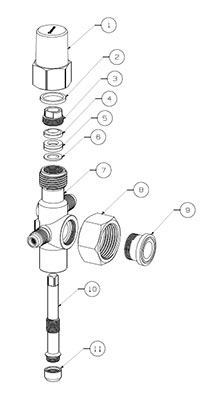

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | |

| 1 | Cap | ABS Plastic / Brass | |

| 2 | Gland Nut | Brass | |

| 3 | Gland Packing | Neoprene | |

| 4 | Gland Packing | Asbestos Free Gasket | |

| 5 | Washer | Brass | |

| 6 | Spindle | Stainless Steel | |

| 7 | Body | Forged Brass (BS-218) | |

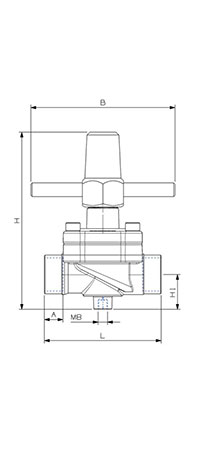

| Part No. | Size (in) |

H (mm) |

H1 (mm) |

L (mm) |

A (mm) |

B (mm) |

WT (kgs) |

|---|---|---|---|---|---|---|---|

| GV-12 | 1/2 | 124.5 | 24.2 | 81 | 13 | 100 | * |

| GV-15 | 5/8 | 124.5 | 24.2 | 81 | 13 | 100 | 0.870 |

| GV-19 | 3/4 | 124.5 | 24.2 | 81 | 13 | 100 | * |

| GV-22 | 7/8 | 124.5 | 24.2 | 81 | 13 | 100 | 0.830 |

| GV-28 | 1.1/8 | 146.5 | 29.5 | 82 | 14 | 110 | 1.142 |

| GV-35 | 1.3/8 | 158 | 33.2 | 96 | 14 | 110 | 1.460 |

| GV-42 | 1.5/8 | 181 | 37.5 | 101 | 14 | 120 | 2.150 |

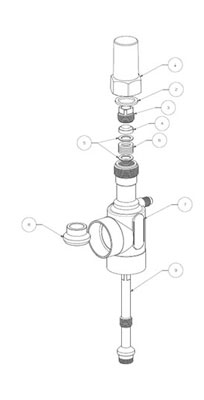

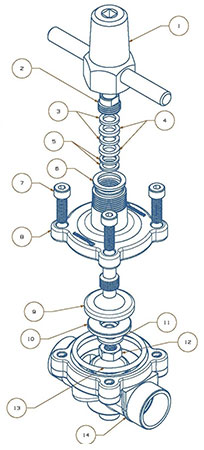

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | |

| 1 | Cap | Steel Plated | |

| 2 | Gland Nut | Extruded Brass | |

| 3 | Gland Packing | Asbestos Free | |

| 4 | Gland Packing | Neoprene | |

| 5 | Gland washer | Brass | |

| 6 | Cap Packing | Neoprene | |

| 7 | Bolt | Steel Plated | |

| 8 | Bonnet | Forged Brass (BS-218) | |

| 9 | Spindle | SS 304 | |

| 10 | Seat | Teflon (PTFE) | |

| 11 | Seat Retainer | Extruded brass | |

| 12 | Spindle Nut | Steel | |

| 13 | Body Packing | ‘O’ Ring Neoprene | |

| 14 | Body | Forged Brass BS-218 | |

| Part No. | A | B | C | D | H1 | H2 | H3 | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|---|---|---|

| RLV- 100-14-10-S -180 | 3/8” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 98 | 38 | 25 | 53.5 | 25.5 | 32 |

| RLV - 100-14-13-S -180 | 1/2” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 102 | 42 | 29 | 53.5 | 25.5 | 32 |

| RLV - 100-14-16-S-180 | 5/8” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 102 | 42 | 29 | 53.5 | 25.5 | 32 |

| RLV - 114-12-19-S -180 | 3/4” ODS | 1-1/4 UNS 12TPI | 7/16UNF | 7/16UNF | 137 | 57 | 40 | 63 | 30 | 40 |

| RLV - 114-12-22-S-180 | 7/8” ODS | 1-1/4 UNS 12TPI | 7/16UNF | 7/16UNF | 137 | 57 | 40 | 63 | 30 | 40 |

| RLV - 114-12-29-S-180 | 1 1/8” ODS | 1-1/4 UNS 12TPI | 7/16UNF | 7/16UNF | 144.5 | 64 | 47 | 63 | 30 | 40 |

| RLV - 134-12-35-S-180 | 1 3/8” ODS | 1-3/4 UN 12TPI | 7/16UNF | 7/16UNF | 180.5 | 79 | 56 | 70 | 34 | 43 |

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | Qty |

| 1 | Cap | Plated Mild Steel | 1 |

| 2 | Washer | Neoprene | 1 |

| 3 | Gland Nut | Brass | 1 |

| 4 | Gland Packing | Neoprene | 1 |

| 5 | Gland Packing | Grafseal | 2 |

| 6 | Washer | Brass | 1 |

| 7 | Body | Brass BS 218 | 1 |

| 8 | Hex nut | Brass BS 218 | 1 |

| 9 | Sleeve | Brass BS218 | 1 |

| 10 | Spindle | S S 304 | 1 |

| 11 | Seat | S S 304 | 1 |

| Part No. | A | B | C | D | H1 | H2 | H3 | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|---|---|---|

| RLV - 100-14-10-S -90 | 3/8” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 98 | 38 | 25 | 53.5 | 25.5 | 32 |

| RLV - 100-14-13-S -90 | 1/2” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 102 | 42 | 29 | 53.5 | 25.5 | 32 |

| RLV - 100-14-16-S -90 | 5/8” ODS | 1”- UNS 14TPI | 7/16UNF | 7/16UNF | 102 | 42 | 29 | 53.5 | 25.5 | 32 |

| RLV - 114-12-19-S -90 | 3/4” ODS | 1-1/4 UNF 12TPI | 7/16UNF | 7/16UNF | 137 | 57 | 40 | 63 | 30 | 40 |

| RLV - 114-12-22-S -90 | 7/8” ODS | 1-1/4 UNF 12TPI | 7/16UNF | 7/16UNF | 137 | 57 | 40 | 63 | 30 | 40 |

| RLV - 114-12-29-S -90 | 1 1/8” ODS | 1-1/4 UNF 14TPI | 7/16UNF | 7/16UNF | 144.5 | 64 | 47 | 63 | 30 | 40 |

| RLV - 134-12-35-S- 90 | 1 3/8” ODS | 1-3/4 UN 14TPI | 7/16UNF | 7/16UNF | 180.5 | 79 | 56 | 70 | 34 | 43 |

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | Qty |

| 1 | Cap | Ms | 1 |

| 2 | Washer | Neoprene | 1 |

| 3 | Gland Nut | Brass | 1 |

| 4 | Gland Packing | Neoprene | 1 |

| 5 | Gland Packing | Graphite | 2 |

| 6 | Washer | Brass | 1 |

| 7 | Body | Brass | 1 |

| 8 | Hex nut | Brass | 1 |

| 9 | Sleeve | Brass | 1 |

| 10 | Spindle | Stainless Steel | 1 |

| 11 | Seat | Stainless Steel | 1 |

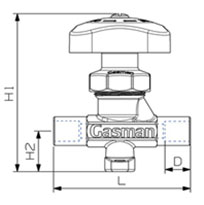

| Part No. | Size (in) | Open H1(mm) | H2 (mm) | L (mm) | A (mm) | B (mm) | Ø (mm) | WT (gm) |

|---|---|---|---|---|---|---|---|---|

| HSV-06 | 1/4 | 69 | 16.50 | 57 | 28 | 60 | 4.5 | 160 |

| HSV-10 | 3/8 | 79 | 19.50 | 64 | 35 | 60 | 5.0 | 210 |

| HSV-12 | 1/2 | 75 | 18 | 80 | 49 | 60 | 5.0 | 290 |

| HSV-15 | 5/8 | 75 | 18 | 80 | 49 | 60 | 5.0 | 300 |

| Part No. | Size (in) | Open H1(mm) | H2 (mm) | L (mm) | D (mm) | WT (gm) |

|---|---|---|---|---|---|---|

| HSV-06S | 1/4 | 69 | 16.50 | 57 | 12 | * |

| HSV-10S | 3/8 | 79 | 19.50 | 64 | 12 | * |

| HSV-12S | 1/2 | 75 | 18 | 76 | 15 | * |

| HSV-15S | 5/8 | 75 | 18 | 80 | 15 | * |

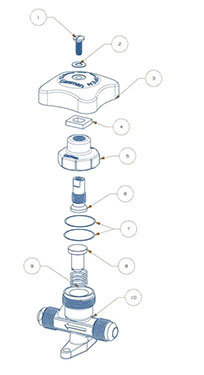

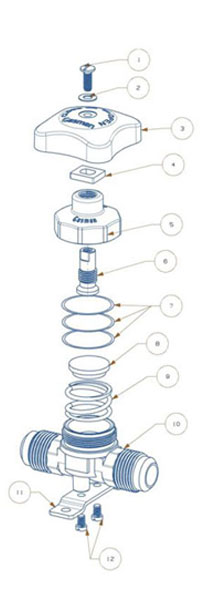

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | |

| 1 | Screw | Steel Plated | |

| 2 | Washer | Steel Plated | |

| 3 | Knob | ABS Plastic | |

| 4 | Washer | Steel Plated | |

| 5 | Bonnet | Forged Brass | |

| 6 | Spindle | Extruded Brass | |

| 7 | Diaphragm | Stainless Steeltd> | |

| 8 | Seat | Stainless Steel | |

| 9 | Spring | Special Treated Steel | |

| 10 | Body | Forged Brass (BS-218) | |

| Material Specifications | |||

|---|---|---|---|

| No. | Part | Material | |

| 1 | Screw | Steel Plated | |

| 2 | Washer | Steel Plated | |

| 3 | Knob | ABS Plastic | |

| 4 | Washer | Steel Plated | |

| 5 | Bonnet | Forged Brass | |

| 6 | Spindle | Extruded Brass | |

| 7 | Diaphragm | Stainless Steeltd> | |

| 8 | Seat | Brass/Nylon | |

| 9 | Spring | Special Treated Steel | |

| 10 | Body | Forged Brass (BS-218) | |

| 11 | Mounting Plate | Steel Plated | |

| 12 | Screw | Steel Plated | |